Aluminium Alloy 7075-T651 Aluminium Plate

Product Introduction

7075 aluminum alloy is one of the strongest aluminum alloys available, making it valuable in high-stress situations. Its high yield strength (>500 MPa) and its low density make the material a fit for applications such as aircraft parts or parts subject to heavy wear. While it is less corrosion resistant than other alloys (such as 5083 aluminum alloy, which is exceptionally resistant to corrosion), its strength more than justifies the downsides.

T651 tempers has fair machinability. Alloy 7075 is heavily utilized by the aircraft and ordnance industries because of its superior strength.

Transaction Information

| MODEL NO. | 7075-T651 |

| Thickness optional range(mm) (length & width can be required) |

(1-400)mm |

| Price per KG | Negotiation |

| MOQ | ≥1KG |

| Packaging | Standard Sea Worthy Packing |

| Delivery Time | Within (3-15) days when releasing orders |

| Trade Terms | FOB/EXW/FCA, etc(can be disscussed) |

| Payment terms | TT/LC,etc. |

| Certification | ISO 9001,etc. |

| Place of Origin | China |

| Samples | Sample can be provided to customer for free, but should be freight collect. |

Chemical Component

Si(0.4%); Fe(0.5%); Cu(1.5%-2.0%); Mn(0.3%); Mg(2.1%-2.9%); Cr(0.18%-0.35%); Zn(5.1%-6.1%); Ai(87.45%-89.92% );

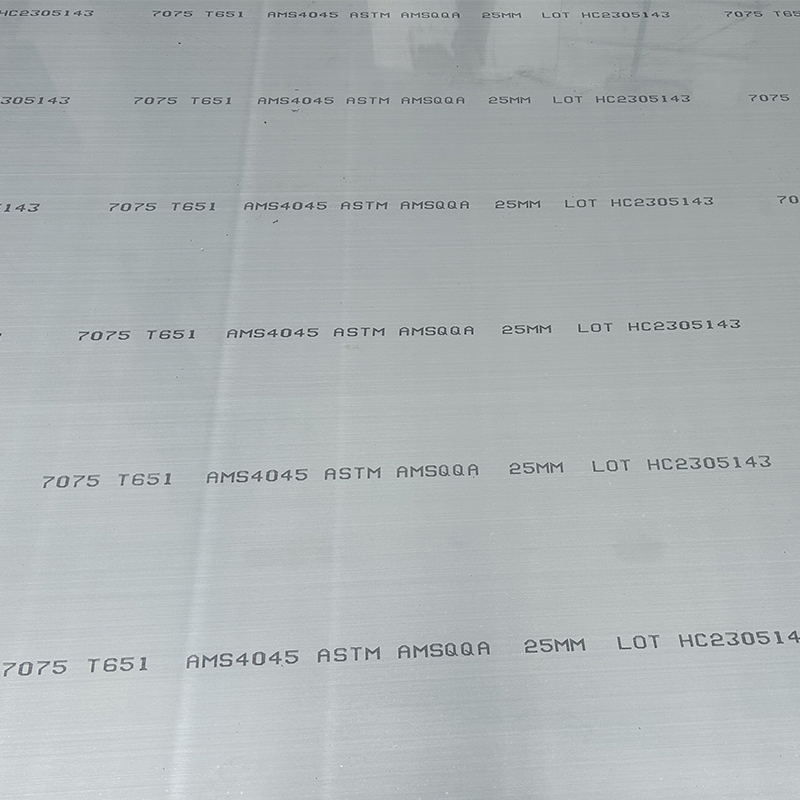

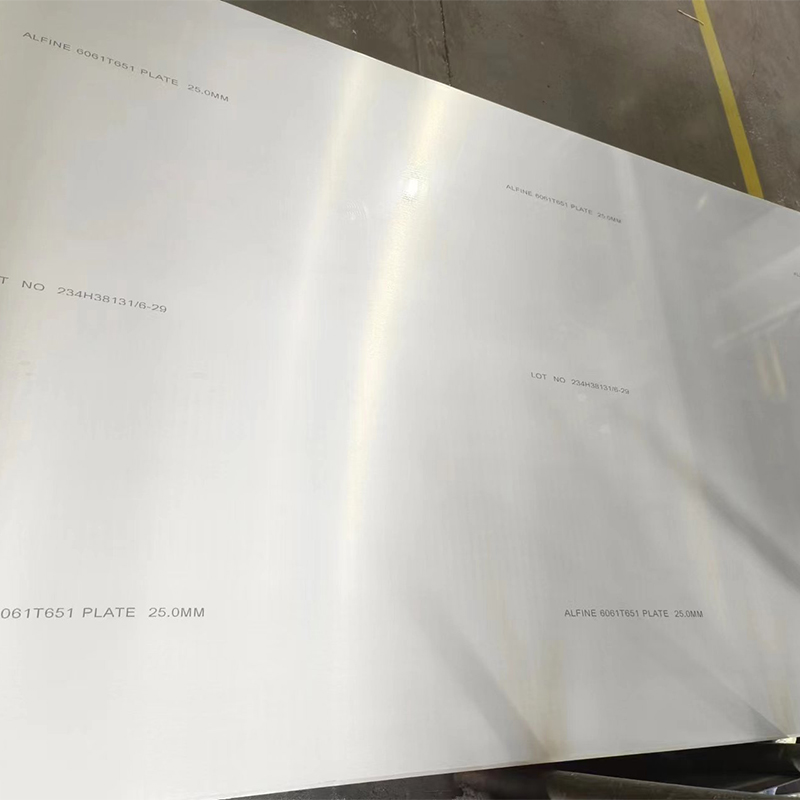

Product Photos

Physical Performance Data

Thermal Expansion(20-100℃): 23.6;

Melting Point(℃):475-635;

Electrical Conductivity 20℃ (%IACS):33;

Electrical Resistance 20℃ Ω mm²/m:0.0515;

Density(20℃) (g/cm³): 2.85.

Mechanical Features

Ultimate Tensile Strength(25℃ MPa):572;

Yield Strength(25℃ MPa):503;

Hardness 500kg/10mm: 150;

Elongation 1.6mm(1/16in.) 11;

Application Field

Aviation, Marine, motor vehicles, electronic communications, semiconductors, metal molds, fixtures, mechanical equipment and parts and other fields.